DIRECT-ACTION PRESSURE REGULATORS FOR MEDIUM AND LOW PRESSURE INLET 18÷0,5 bar - OUTLET 4÷0,016 bar

DIRECT-ACTION PRESSURE REGULATORS FOR MEDIUM AND LOW PRESSURE INLET 18÷0,5 bar - OUTLET 4÷0,016 bar

PILOT-OPERATED PRESSURE REGULATORS FOR MEDIUM AND LOW PRESSURE PRESSURE : INLET 18÷0,2 bar - OUTLET 8÷0,016 bar

PILOT-OPERATED PRESSURE REGULATORS FOR MEDIUM AND LOW PRESSURE PRESSURE : INLET 18÷0,2 bar - OUTLET 8÷0,016 bar

PILOT-OPERATED PRESSURE REGULATORS FOR HIGH PRESSURE PRESSURE : INLET 75÷0,5 bar - OUTLET 25÷0,3 bar

PILOT-OPERATED PRESSURE REGULATORS FOR HIGH PRESSURE PRESSURE : INLET 75÷0,5 bar - OUTLET 25÷0,3 bar

PILOT-OPERATED PRESSURE REGULATOR WITH TIME PROGRAMM

PILOT-OPERATED PRESSURE REGULATOR WITH TIME PROGRAMM

GAS GOVERNOR

GAS GOVERNOR

The gas, due to transportation or production needs, are available for use at pressure values which are variable and higher than the needed ones.

Pressure reduction can be obtained with a normal organ of interception, which, appropriately throttled, causes a pressure drop, which however turns out to be variable with the varying of the flow and of the upstream pressure.

This dual function, of reduction and of regulation of the pressure to a constant value, irrespective of the variation of the value of the upstream pressure and of the flow rate, is obtained with the reducing pressure regulators, having specific characteristics in relation to the flow rates and pressures.

When a constancy of a very high pressure value is required, or for technical reasons, it is recommended to carry out the reduction in two or more steps (typical of the LPG control units), which consists in the distribution of the pressure drop on two or more regulators in series.

As security system in the decompression of the gas, two regulators are installed in series (typical of the NG stations). This type of application with emergency regulator installed upstream of that service, avoids overpressure of valley for faulty operation from that service.

We have pressure regulators for LPG, NG, etc., to satisfy any need for pressure and flow.

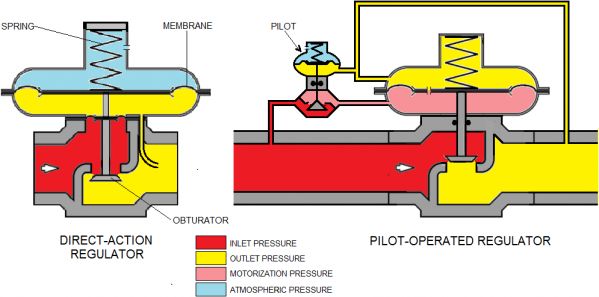

DIRECT-ACTION REGULATOR

The apparatus consists of the mobile shutter unit, which more or less opens the passage in the orifice and the membrane, integral with the shutter, which constitutes the element of comparison between the force generated by the downstream pressure with the overlying force supplied from the load, which can be a weight, a spring or an auxiliary pressure.

PILOT-OPERATED REGULATOR

The apparatus consists of the mobile obturator group, which more or less opens the passage in the orifice and the membrane, integral with the obturator which constitutes the element of comparison between the force of the pressure generated by the pilot with the overlying force generated by the pressure of the valley and the spring. Spring that keeps the passage in the orifice closed at zero flow.

The pilot has a double function: on the one hand, it compares the regulated downstream pressure with the preset calibration value, consisting of the force of the spring; on the other hand, as a function of the calibration pressure, it generates the motorization pressure that moves the shutter away from the orifice to maintain the pressure at the calibration value as a function of the flow rate.